Doing just the edges (side AND base) will, as

@François Pugh points out, end up in a long bevel and you can actually extend that bevel into the P-Tex depending what tools you are using. If you want to keep the base bevel from becoming too 'long' and setting a bevel in the P-Text, you need to remove P-Tex with a base grind.

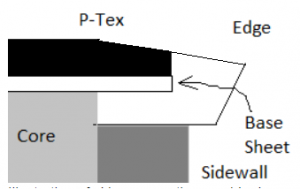

Illustration of ski cross section, upside down

NOTE: For the sake of clarity I have removed the base sheet, core and sidewall from illustrations below.

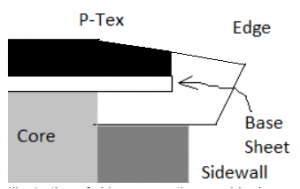

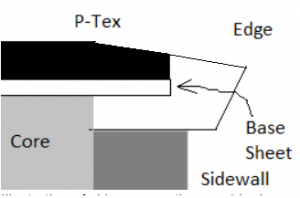

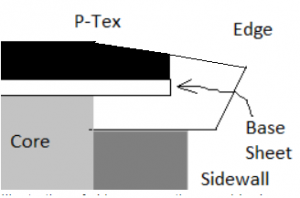

You can get your skis sharper just doing the side edges. As you remove side edge you also move the corner of the edge in towards the base thus effectively removing the likely slightly rounded portion of the base edge. Not all of it necessarily, but enough to create a more distinct and angular transition from base to side edge.

Illustration of a rounded edge

Illustration of a rounded edge after side file/stone only, partial round edge removal

Illustration of rounded edge after more aggressive side file/stone only; complete round edge removal

If you just polish your base edge to remove the outies and smooth out some of the roughness you don't remove much material. If you only use medium to fine diamond stones on both edges, you remove burrs and freshen the corner of the edge. Depending on how sharp you need them, just a fine stone can do the trick. If you have significant damage or need really sharp for ice, you'll end up taking of more material. Until you use a file or a very coarse diamond stone, you aren't removing that much material from the edges and won't develop the 'long bevel'.

Illustration of a 'long bevel'

Changing from a 2* to a 0.5* requires a lot of P-Tex removal even if the bases are flat and the base edge is flush with the base where they meet. You have to lower the P-Tex side of the base edge sufficiently that you can form the 0.5* bevel. That means repeatedly trying to set the base bevel to 0.5* interspersed with base grinds. The reason to remove base, then edge, then base then edge is to protect the stone from excessive contact with the edge which shortens the life of the dressing on the stone and puts structure into the edge. In the illustration below all of the material illustrated in gray needs to be removed to permit the base bevel to go from 1* to 0.5* along with the metal edge between the 1* and 0.5* lines.

Illustration of edge and P-Tex required to be removed to change base edge bevel

Base grinds only need to remove a lot of material if you are changing a base bevel from a higher number to a lower one or your bases are convex. In either case you'll end up with a flat base that is flush with the inside of the base edge. I've mentioned elsewhere that I do a base grind quite frequently on my skis yet the base grinds don't end up being the reason the skis are retired.

What this all boils down to is that you have to visualize the desired results of the work done and determine whether you can deal with a long bevel or not and how sharp you need your edges. Toss in dealing with innies (missing edge material), rounded edges and convex bases. All said, it is a complex scenario to get every ski into the desired condition. You need to look at the base and edges after each pass of a tool or a machine process to evaluate if you have taken enough off for the desired results.